2-TLX XL + Flex Frame 2.5” (Rails)

-

COMPACT

-

HIGHLY VERSATILE

-

EASY TO ASSEMBLE

The 2-TLX XL + Flex Frame 2.5″ Setup includes a dedicated 2.5″ rails Flex Frame. It is distinct from the Flex Frame 3.0 and is specifically designed for use with 2.5″ rails. The Flex Frame 2.5″ offers improved maneuverability due to its slimmer up/down and left/right assemblies. It is recommended for use in tight areas. For enhanced durability and versatility, the 2-TLX XL + Flex Frame 3.0 (4″ rails) Setup is a preferred choice. Additionally, the Flex Frame 3.0 (4″ rails) is also compatible with 2.5″ rails, making it highly versatile.

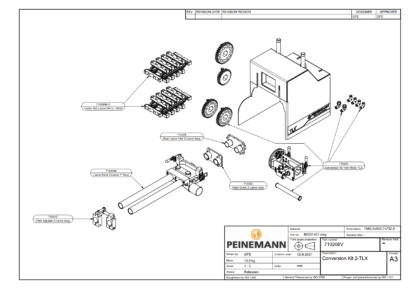

One "2-TLX XL + Flex Frame 2.5'' (Rails)" contains the following items:

Part Number: 460048744

Part Number: 524635011

Part Number: 524635021

Required quantity of 4, for Scaffolding and Vertical H-Frame Setup

Part Number: 1000.560P

Description

The 2-TLX XL + Flex Frame 2.5″ Setup includes a dedicated 2.5″ rails Flex Frame. It is distinct from the Flex Frame 3.0 and is specifically designed for use with 2.5″ rails. The Flex Frame 2.5″ offers improved maneuverability due to its slimmer up/down and left/right assemblies. It is recommended for use in tight areas. For enhanced durability and versatility, the 2-TLX XL + Flex Frame 3.0 (4″ rails) Setup is a preferred choice. Additionally, the Flex Frame 3.0 (4″ rails) is also compatible with 2.5″ rails, making it highly versatile.

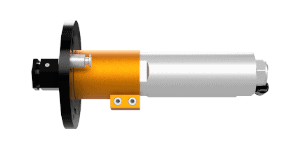

The Peinemann Dual Lance Feeder (2-TLX) from the TLX series sets the standard as the industry’s lightest, strongest and most versatile tube feeder. Its innovative modular design, featuring an ultra-light carbon fiber drive unit, achieves a remarkable 30% reduction in weight and an increase in strength compared to previous models. The interchangeable gear drive system provides 25% additional speed and power control, allowing for up to 130 kg of push/pull strength in slow gear mode with just one motor. As such, the 2-TLX is a true all-in-one powerhouse. Moreover, its highly adaptable design facilitates swift assembly, tool-free cartridge replacement and hassle-free maintenance. Additionally, the Peinemann 2-TLX is ATEX-approved and expertly assembled in the Netherlands. Furthermore, converting the 2-TLX into various configurations such as Single Pipe (1-TLX), Triple Lance (3-TLX), Quadruple Lance (4-TLX) or Quintuple Lance Feeder (5-TLX) is a seamless process with the TLX series. Thanks to its modular design, the 2-TLX can be effortlessly transformed using conversion kits specifically designed for each configuration. This ensures a smooth and straightforward conversion process, allowing operators to adapt the equipment to different requirements with ease.

The Peinemann Flex Frame 2.5″ complements this setup as a highly compact indexing frame for industrial cleaning operations. With its innovative design and durable components, the Flex Frame 2.5″ offers precise motorized indexing. Its modular features ensure adaptability and compatibility with a wide range of Peinemann cleaning equipment, including the TLX and XLTC. It is distinct from the Flex Frame 3.0 and is specifically designed for use with 2.5″ rails. The Flex Frame 2.5″ offers improved maneuverability due to its slimmer up/down and left/right assemblies. With lightweight components, the Flex Frame 2.5″ is easily transportable and can be assembled by hand, increasing its portability and ease of use.

Specifications 2-TLX XL

| General | |

| Length (drive unit) | 46.5 cm (18.3 in) |

| Width (drive unit) | 26.5 cm (10.4 in) |

| Height (drive unit) | 42.0 cm (16.5 in) |

| Weight (drive unit incl. motor) | 27kg (59.5 lb) |

| Hose feed rate | 12.5 – 33 cm/s (4.9 – 12.9 in/s) |

| Max. push/pull force | 200 kg (441 lb) |

| Pitch adjustment range | 35 – 80 mm (1.38 – 3.15 in) |

| Motor | |

| Motor model | Atlas Copco LZB46-ML-AR004-50 |

| Max. output | 0.62 kW (0.83 hp) |

| Min. air pressure | 3.0 bar (43.5 psi) |

| Operating air pressure | 6.3 bar (91.4 psi) |

| Max. air pressure | 7.0 bar (101.5 psi) |

| Max. air consumption | 7.9 l/s (16.7 cfm) (15.8l/s (33.5 cfm) in total with 2 motors) |

| Stall torque | 32 Nm (23.3 ft lb) |

| Vane type | Lubrication free |

| Hose specifications | |

| Hose size | 8/4 – 10/4 |

| Hose outer diameter | 14 – 19 mm (0.55 – 0.75 in) |

| Max. hose coupling diameter | 25 mm (2.17 in) |